ASME SA213 T11 cold drawn seamless steel tube is a high-performance alloy steel product widely used in high-temperature and high-pressure service environments. Thanks to its excellent mechanical strength, thermal stability, and oxidation resistance, this material plays a critical role in industries such as power generation, petrochemical processing, and boiler manufacturing. This article provides a comprehensive overview of ASME SA213 T11 cold drawn seamless tubes, covering material properties, production processes, applications, and market outlook.

ASME SA213 T11 is a low-alloy chromium-molybdenum steel. Its chemical composition typically includes 1.00%–1.50% chromium and 0.44%–0.65% molybdenum. This optimized alloying design gives the material outstanding high-temperature strength and excellent resistance to oxidation.

After proper heat treatment, ASME SA213 T11 steel tubes achieve a tensile strength of more than 415 MPa and a yield strength of at least 205 MPa at room temperature. Even at elevated temperatures up to 593°C, the material maintains good creep rupture strength, making it significantly superior to conventional carbon steel. In addition, T11 steel offers good weldability and machinability, allowing for easier fabrication, installation, and long-term maintenance.

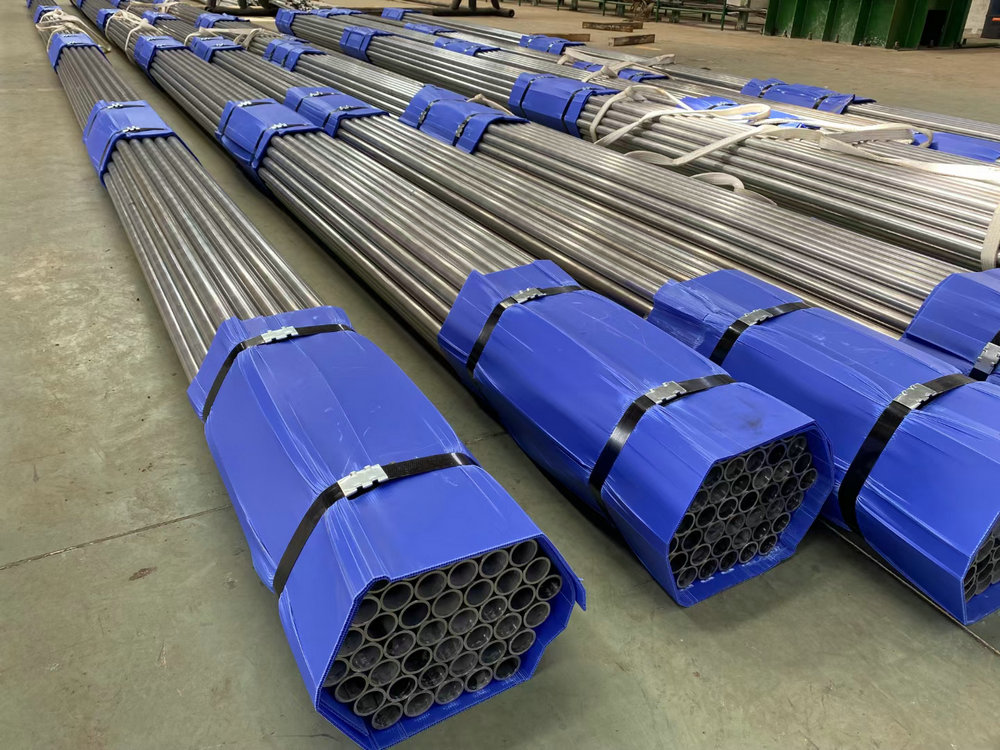

The cold drawing process is a key factor in ensuring the superior quality of ASME SA213 T11 seamless tubes. Compared with hot-rolled pipes, cold drawn tubes provide higher dimensional accuracy and better surface finish.

Production begins with piercing a solid round billet to form a hollow tube blank. The tube blank then undergoes multiple cold drawing passes to gradually reach the required outer diameter and wall thickness. Intermediate annealing is performed between drawing stages to eliminate work hardening and restore ductility. Finally, the finished tube is heat treated—typically by normalizing followed by tempering—to achieve optimal mechanical properties and microstructural uniformity. Strict control of temperature and deformation parameters throughout the process ensures stable and reliable product performance.

ASME SA213 T11 cold drawn seamless tubes are subjected to comprehensive quality inspection procedures. These typically include ultrasonic testing for internal defects, eddy current testing for surface imperfections, and hydrostatic testing to confirm pressure resistance. Mechanical property testing and metallographic examination are also carried out to verify compliance with standard requirements.

Due to the cold drawing process, these tubes offer excellent dimensional precision. Outer diameter tolerances are commonly controlled within ±0.10 mm, while wall thickness tolerances are maintained within −0/+10%. This high level of accuracy greatly improves installation efficiency and service reliability.

ASME SA213 T11 seamless steel tubes are primarily used in power station boilers for manufacturing superheaters, reheaters, and headers that operate under high temperature and pressure. In the petrochemical industry, they are widely applied in equipment such as hydrogenation reactors and cracking furnace tubes.

These applications generally require materials to withstand long-term service at temperatures between 500°C and 600°C while enduring high internal pressure. With its excellent heat resistance and sufficient mechanical strength, ASME SA213 T11 fully meets these demanding operating conditions. In recent years, the development of supercritical and ultra-supercritical power generation technology has further driven demand for this grade of alloy steel tube.

As global energy structures evolve and environmental regulations become increasingly strict, high-efficiency and cleaner coal-fired power generation technologies will continue to play an important role for the foreseeable future. This creates a stable and long-term demand for ASME SA213 T11 seamless steel tubes.

Industry data indicate that annual demand for high-end boiler tubes remains substantial, with chromium-molybdenum alloy steel tubes accounting for a significant share. In addition, ongoing infrastructure development in emerging markets is expected to further support export growth for ASME SA213 T11 products.

Steel tube manufacturers are actively investing in advanced production technologies to enhance efficiency and product quality. Innovations such as improved rolling and piercing techniques, online heat treatment systems, and intelligent inspection technologies have significantly improved yield rates, reduced energy consumption, and enhanced overall quality control. These advancements not only strengthen product competitiveness but also provide greater reliability for end users.

Although ASME SA213 T11 steel tubes offer excellent performance, proper installation and maintenance are essential. During welding, matching filler materials should be used, and preheating and interpass temperatures must be carefully controlled. During service, regular inspections should be conducted to monitor creep deformation and overall condition. Establishing a comprehensive lifecycle management system helps ensure safe and reliable long-term operation.

ASME SA213 T11 cold drawn seamless steel tube represents a high-end alloy steel solution characterized by advanced technology, complex manufacturing processes, and high application value. As manufacturing capabilities continue to improve, the quality and performance of ASME SA213 T11 products will further advance, providing strong support for the global energy and industrial sectors. With continuous innovation and strict quality control, ASME SA213 T11 steel tubes are well positioned to gain broader recognition in the international market.

None