Introduction

Hardness is one of the most critical mechanical properties for evaluating the performance of steel pipes. It reflects a material’s ability to resist deformation, wear, and surface indentation. For steel pipes used in construction, oil and gas, heat exchangers, and pressure systems, hardness directly affects durability, machinability, and corrosion resistance.

1. What Is Hardness in Steel Pipes?

Hardness refers to a material’s resistance to indentation by a harder object. For steel pipes, hardness is often linked with tensile strength and wear resistance — the higher the hardness, the better the pipe performs under mechanical stress and abrasive conditions. However, overly high hardness can reduce toughness, leading to brittleness, so balance is key.

2. Common Hardness Testing Methods for Steel Pipes

Brinell Hardness (HB)

The Brinell test is often used for thick-walled or heavy-section steel pipes. A 10 mm hardened steel ball is pressed into the surface under a 3000 kg load. The resulting indentation area determines the hardness value, expressed in N/mm². Brinell hardness is suitable for structural and alloy steels.

Rockwell Hardness (HR)

The Rockwell test is more commonly used for finished or heat-treated steel pipes. It measures indentation depth rather than diameter, making it faster and more practical for industrial use.

HRA: For high-hardness materials like cemented carbides.

HRB: For low-hardness materials such as annealed steel.

HRC: For quenched or hardened steel pipes.

Rockwell C (HRC) is typically applied to hardened or high-strength alloy steel pipes used in demanding environments.

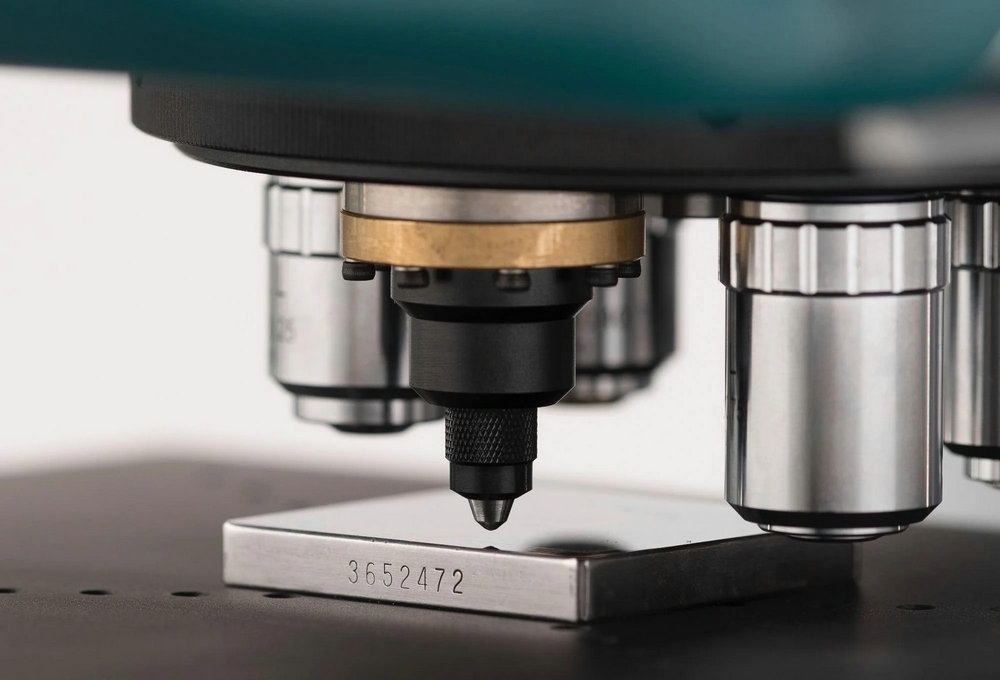

Vickers Hardness (HV)

The Vickers method uses a diamond pyramid indenter to measure the hardness of steel surfaces, especially for thin-walled pipes or small samples. It provides highly accurate results and is suitable for laboratory evaluations.

3. The Relationship Between Hardness and Strength

In steel pipes, hardness and strength are closely correlated. Hardness represents a material’s resistance to plastic deformation, while tensile strength reflects its ability to withstand stress. Generally, higher hardness means higher tensile strength. This relationship helps engineers estimate pipe performance based on hardness test data.

4. Why Hardness Testing Is Important for Steel Pipes

Quality Control: Ensures consistent mechanical properties.

Heat Treatment Verification: Confirms correct hardening, annealing, or tempering.

Wear Resistance Evaluation: Predicts service life in abrasive or high-pressure environments.

Material Selection: Helps engineers choose suitable pipe grades for specific industrial uses.

Conclusion

Understanding hardness and selecting the appropriate test method are essential for assessing steel pipe quality and performance. Whether you use Brinell for structural pipes, Rockwell for hardened ones, or Vickers for precise measurement, hardness testing ensures reliability and safety across industrial applications.