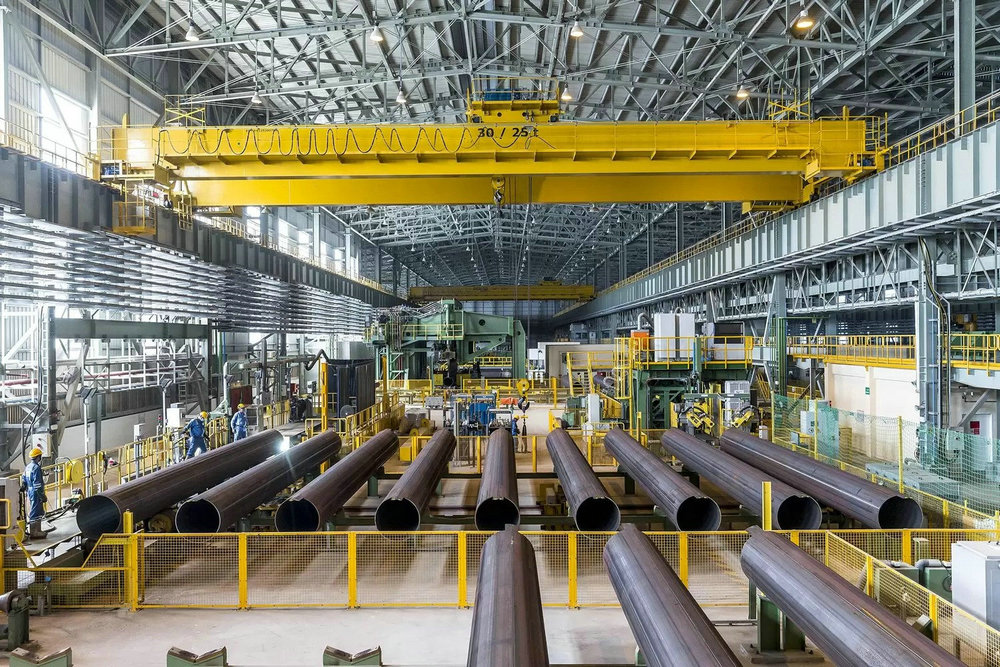

Longitudinal Submerged Arc Welding (LSAW) pipes are one of the most reliable and durable types of steel pipes used in oil, gas, and structural applications. Known for their excellent strength, precision, and safety, LSAW pipes play a vital role in energy infrastructure and heavy engineering industries. This article explores their production process, material selection, technical advantages, and key differences from other welded pipes.

The production of LSAW pipes follows a rigorous multi-step procedure to ensure quality, precision, and reliability.

High-quality steel plates that meet ASTM and API 5L standards are selected for their superior toughness, weldability, and corrosion resistance. These plates are tested for chemical composition, strength, and impact performance.

The plate edges are precisely machined and beveled for accurate welding. Then, the steel plate is mechanically rolled into a cylindrical shape, ensuring consistent diameter and minimal residual stress.

Using a submerged arc welding process, multiple welding passes are performed along the pipe’s length. This technique produces deep, uniform welds with outstanding mechanical integrity, ideal for high-pressure and high-temperature environments.

Ultrasonic and radiographic testing detect internal or surface defects such as porosity or cracks. Each pipe undergoes a hydrostatic pressure test to confirm its structural integrity and leak-proof performance.

Geometric accuracy—including straightness, roundness, and wall thickness—is verified. Finally, the pipe surface is cleaned and coated (commonly with Fusion-Bonded Epoxy, FBE) to improve corrosion resistance.

Each LSAW pipe is marked with full traceability data such as size, grade, and batch number. Protective coatings and proper packaging prevent mechanical damage during transport.

Different grades of steel are used based on project demands:

Carbon Steel (ASTM A53-B, API 5L PSL1/2): Cost-effective and widely applicable for general fluid transportation.

Alloy Steel (ASTM A335 P11/P22): Excellent strength for high-pressure and elevated-temperature applications.

Stainless Steel (TP304, TP316): Ideal for corrosive or marine environments.

High-Strength Low-Alloy (HSLA) Steel (API 5L X60–X80): Offers an optimal balance of weight and strength.

Duplex Stainless Steel (UNS S32205/S32750): Combines corrosion resistance with high tensile strength, perfect for offshore pipelines.

When compared with Electric Resistance Welded (ERW) and Spiral Submerged Arc Welded (SSAW) pipes, LSAW pipes demonstrate several key advantages:

Superior Structural Strength: The longitudinal weld provides consistent strength and better pressure resistance.

Excellent Dimensional Accuracy: Plate forming ensures high precision in diameter and thickness control.

High Durability: Double-sided submerged arc welding and full non-destructive testing ensure low defect rates.

Corrosion Resistance: Internal and external coatings extend service life in harsh environments.

Large Diameter Capability: Up to 56 inches (1422 mm) with wall thickness up to 50 mm, ideal for large-scale projects.

LSAW pipes comply with API 5L specifications that define:

Product Specification Levels (PSL1, PSL2) — PSL2 has stricter quality control.

Material Grades (X42–X80) — Indicate yield strength levels.

Tight Dimensional and Chemical Tolerances — Reduced phosphorus and sulfur for better toughness and corrosion resistance.

Mechanical Property Testing — Includes tensile, bend, and impact tests.

LSAW pipes are widely used in:

Oil & Gas Transmission Lines

Petrochemical and Refinery Projects

Water Supply and Sewage Systems

Bridge, Port, and Offshore Structures

High strength and reliability under extreme pressure

Excellent weld integrity and sealing performance

Long lifespan with minimal maintenance

Suitability for long-distance, high-capacity pipelines

As global energy infrastructure evolves, demand for high-strength, corrosion-resistant, and large-diameter steel pipes continues to rise. With innovations in automated welding, non-destructive inspection, and smart coating technologies, LSAW pipes will remain a cornerstone material in oil, gas, and renewable energy transportation systems.

Longitudinal Submerged Arc Welding (LSAW) pipes combine precision engineering, superior strength, and reliable performance. Their ability to withstand extreme conditions makes them indispensable in modern industrial and energy projects. Choosing the right LSAW pipe grade ensures both operational safety and long-term cost efficiency.